Valentine’s Day presents some unique logistical challenges. Here’s how the supply chain rises to the occasion to get roses and chocolate covered strawberries to their destination on time through the cold chain.

Valentine’s Day presents some unique logistical challenges. Here’s how the supply chain rises to the occasion to get roses and chocolate covered strawberries to their destination on time through the cold chain.

Valentine’s Day doesn’t happen by magic. All those flowers, strawberries, and chocolates get into the hands of consumers thanks to the cold chain. Since so many traditional Valentine’s Day gifts are perishable, the logistics that prop up the holiday require a little more planning and precision than usual.

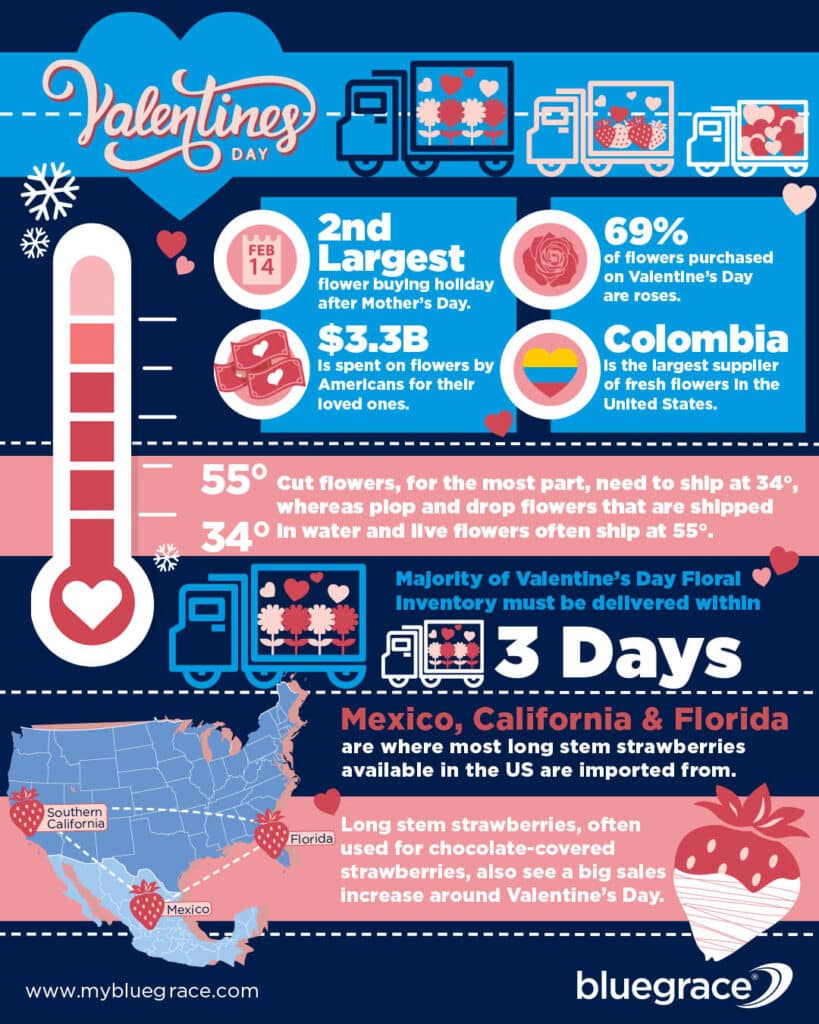

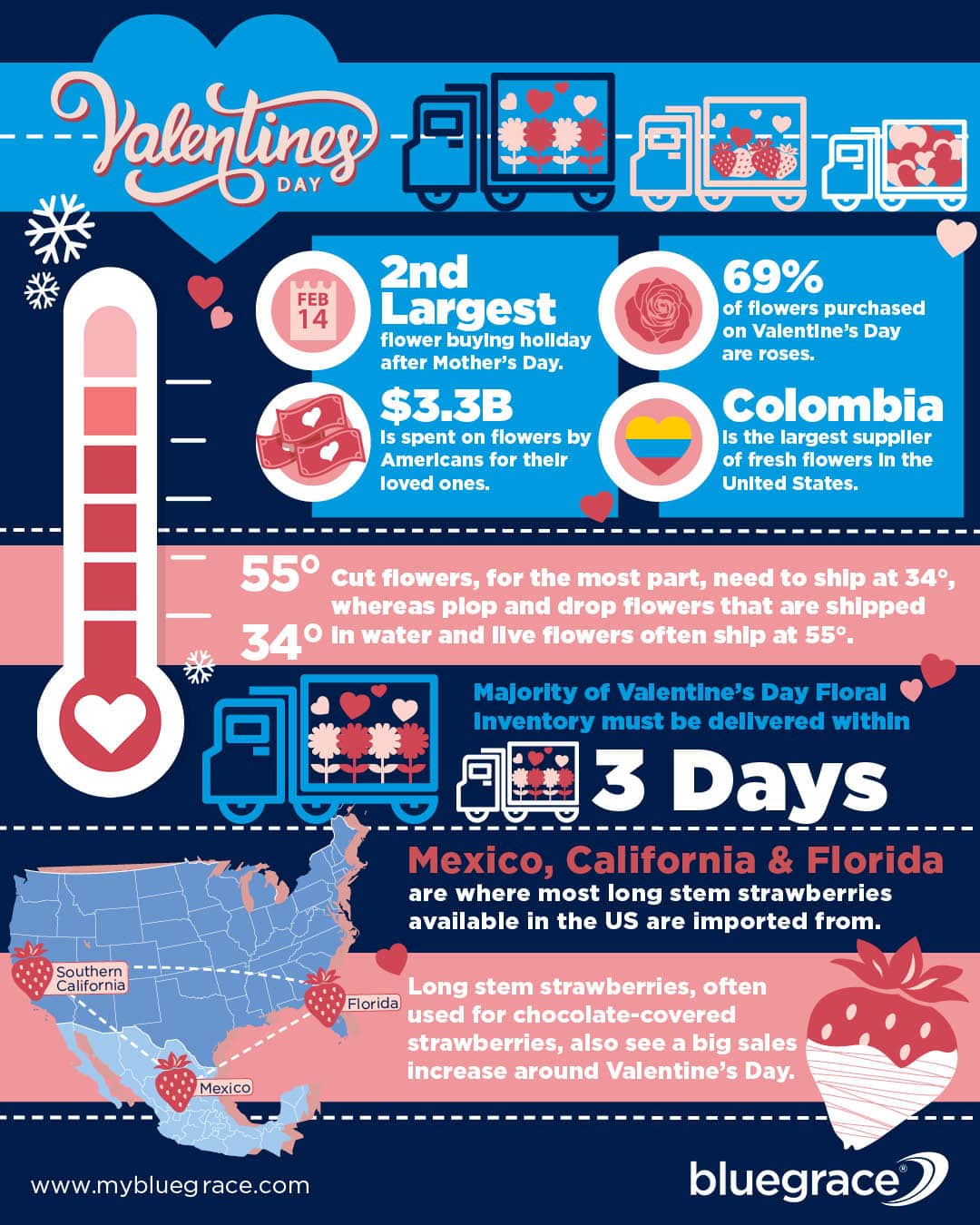

With Valentine’s Day being the 2nd largest flower-buying holiday after Mother’s Day, it accounts for a good percentage of that spending.

Estimates from last year showed that Americans would spend approximately $3.3 billion on flowers for the special people in their lives, and with Valentine’s Day being the 2nd largest flower-buying holiday after Mother’s Day, it accounts for a good percentage of that spending. Long stem strawberries, like the ones often used for chocolate-covered strawberries, also see a big sales increase around Valentine’s Day.

Valentine’s Day logistics are made more complicated by the perishable nature of many of the most popular gift categories and the short delivery window. A lot of resources go into not only bringing in larger than usual quantities of goods all at once but also planning for the rush and overcoming the challenges that come along with it.

Trucking Capacity

In today’s market, the average day guarantees tight trucking capacity. The driver shortage and increased demand during the pandemic have led to extremely tight trucking capacity, and while it looks like we may be headed in the right direction, the holiday’s shipping surge this year will still add a lot of extra pressure to the market. This tight capacity puts pricing power in carriers’ hands.

Physical Space for Shipping and Delivery

Finding the space to sort, pack, and ship these products is no picnic.

Warehouse space is in high demand, and vacancy rates for industrial spaces are near a record low. With that in mind, where do all the flowers and strawberries go prior to heading to their destination? Finding the space to sort, pack, and ship these products is no picnic.

An Extremely Short Season

Because so many of the traditional gifts given on this holiday are perishable, the window to get them into the country, out to their destinations, and then carry out final mile delivery is very short. The vast majority of Valentine’s Day inventory of flowers must be delivered within a 3-day window.

As you can imagine, that eats up a lot of trucking capacity, specifically impacting reefer capacity since so many of these products need to stay cold. It also means that additional space is only needed for a few weeks to a few days. Finding resources to cover such a short, solid cold chain surge is tricky.

Shippers Must Account for the Surge

Shippers’ operations are built to effectively cover static demand. When demand surges for an event like Valentine’s Day, those shippers need to ramp up their operations. This oftentimes means working around the clock and hiring seasonal help to keep up.

The cut flowers we see in stores during the cold winter months are grown around the world and imported by air freight into the United States, with Miami International Airport serving as the import point for most cut flowers. Colombia is the US’s largest supplier of fresh flowers, with roses being the most popular flower variety for the holiday. 69% of flowers purchased for Valentine’s Day are roses, according to The Society of American Florists.

From there, flowers travel by truckload to various warehouses and distribution centers. Since fresh-cut flowers are very perishable, keeping them at the appropriate temperature throughout their entire journey is critical to a sale-able final product, and the temperature depends on the variety and presentation. Cut flowers, for the most part, need to ship at 34°, whereas plop and drop flowers that are shipped in water and live flowers often ship at 55°.

Most long stem strawberries available in the US in February are imported from Mexico, though some are grown in southern California and Florida, as well. They’re sold to both retail stores for sale directly to consumers and to other retailers who sell chocolate-covered strawberries.

Demand planning for Valentine’s Day begins about a year ahead of time. Projections must be made and orders put in very early compared to most products so that farmers can plant to accommodate the expected demand.

The capacity planning goes beyond the holiday itself, too.

At BlueGrace, we work with our customers and plan alongside them to make sure they’re ready for any holiday surge so they’re able to avoid the spot market during a time when capacity is extra tight.

The capacity planning goes beyond the holiday itself, too. The flowers and strawberries purchased for Valentine’s Day must then be restocked to cover static demand.

Get expert logistics insights delivered straight to your inbox

"*" indicates required fields