The complexity of supply chains has progressed globally over the last decade, growing from simple domestic supply chains to increasingly involved global supply chains. This tremendous change has also exposed logistics to several vulnerabilities and disruptions. Shippers, retailers, and customers should expect to have visibility into their operations for various purposes, from foreseeing delays to having the ability to track-and-trace their freight.

As the economy continues to rebuild, visibility is key to surviving capacity crunch and supply chain inconsistencies.

As the economy continues to rebuild, visibility is key to surviving capacity crunch and supply chain inconsistencies. While industries have tried to create a real-time information flow for decades, both the needs and the opportunities to achieve this are higher than ever.

The Main Reasons For A Disrupted Supply Chain

There are two significant conditions that drive disruptions in the supply chain. The first is natural occurrences such as pandemics, earthquakes, floods, hurricanes, and wildfires. The second is social disputes such as trade wars, labor disputes, and politics.

The Covid-19 pandemic disrupted many businesses by making them privy to unexpected challenges such as restrictions, container shortages, truck driver shortages, and port congestions even as global demand increased.

There is a need to change how the supply chain operates and transports goods, brought forth by developments seen in demand-consumer patterns. Brick and mortar operations have shifted to E-commerce, and remote versus in-house customer interaction has largely disrupted the norms within the supply chain industry.

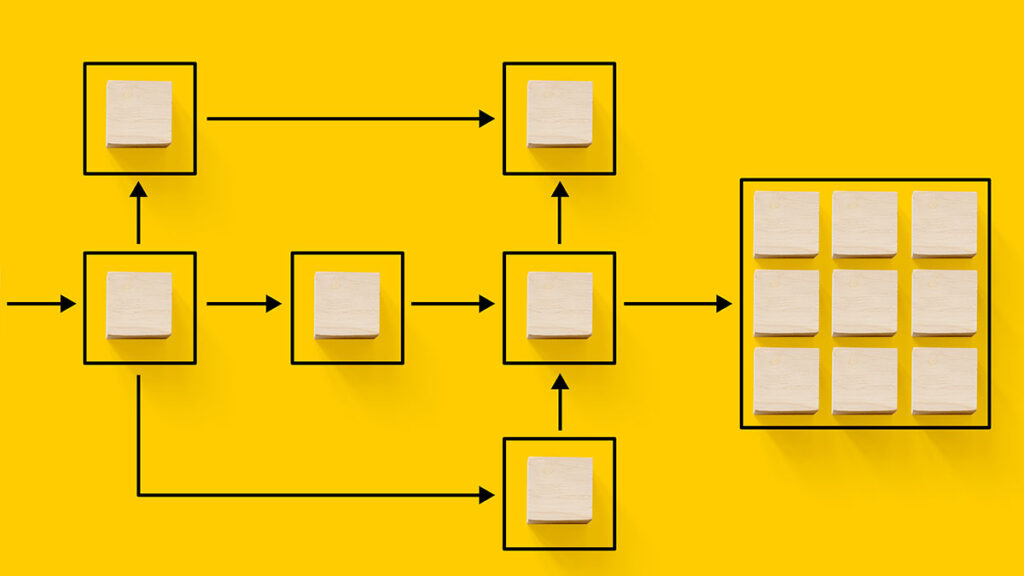

Due to its traditional and outdated practices, the logistics industry has demonstrated a conservative acceptance of the use of new technologies and continues to suffer from a lack of streamlining data and data standardization. Companies would benefit from sharing data among stakeholders in the supply chain. In its current, siloed process, it flows in a series of opaque steps from raw material to manufacturer to finally the customer. Most companies have only 20% visibility into their supply chains, which is mostly restricted to their immediate relationships.

Such outdated practices expose the market to increased disruptions if companies are unprepared to handle critical challenges. Lack of automation, for instance, results in a deluge of phone calls, faxes, and emails for tracking loads, making data management challenging and time-consuming. The lack of digitization also causes a disconnect in visibility, as this complicates tracking loads and reacting flexibly with rerouting or ETA. There is no trustworthy forecast for risk prevention.

Companies also miss out on data-based insights necessary for internal and external operations due to a lack of streamlining data. In the absence of standardized data, companies lack valuable optimization as data streams are collected and stored without being utilized. Meanwhile, issues created by legacy software currently in operation continue to create digital bottlenecks.

What Visibility Can Do For The Logistics/Trucking Industry

Visibility can help shippers plan for load allocation. Shippers can optimize truckload capacity demand and intelligently allocate loads to the spot market based on market conditions. With end-to-end visibility, logistics stakeholders could even plan through freight delays. Real-time tracking makes this possible, while increasing efficiency and risk anticipation.

Overall supply chain visibility enables the industry to track raw materials and components from original suppliers and manufacturers through to end customers.

Increased supply chain visibility poses a plethora of benefits.

- It minimizes disruption and errors by ensuring minimal interruption in processes, while providing quick and flexible responses to any requirement—such as redirection of supply throughout the value chain. It also ensures that you can re-evaluate areas of inefficiency and reduce risks.

- Rich insights that stem from visibility can track performance expectation and estimate future demand to ensure that performance is optimized, and future goals are met.

- Increased communication that facilitates information sharing between departments and organizations can help spot problems and gaps in the system.

A supply chain digitalization is inevitable for increasing visibility, as it ensures complete and real-time visibility into extended supply networks.

Such flexibility is the key to meeting and accommodating customer needs by providing real-time help.

Automated tools drive this change by creating smarter supply chains. A supply chain operating on a solid foundation of data analysis, and open communication lines, can help avoid bottlenecks and disruption. Such flexibility is the key to meeting and accommodating customer needs by providing real-time help. The power of tracking can be harnessed to receive up-to-the-minute updates crucial for specific industries, shipments, and services such as dynamic routing.

How To Gain Visibility To Build A Resilient Supply Chain

The biggest problem with the supply chain has been collecting and storing relevant information in a suitable format and place. Tracking goods through a long supply chain is challenging, primarily when each company uses a different software package for each application. In this case, traceability and transparency can guarantee a seamless supply chain void of disruptions and delays.

The first step is to define the organization’s goals concerning their need for IT setup. This can help them decide where to invest in an appropriate supply chain software that can be interfaced with suppliers’, logistics partners’, and other corporate software. The organization must also decide on an appropriate data conversion method, such as electronic data interchange (EDI) or via the more-advanced APIs. This will allow corporate systems to read and use information from other stakeholders in the ecosystem.

IoT can be used for direct tracking. RFID technology can be connected to IoT sensors, enabling real-time tracking and monitoring of the location and status of shipments. IoT devices can also monitor temperature, moisture, shock loads, and other parameters essential for ensuring the safety and integrity of the vehicle.

Driver tracking software can be used to trace freight assigned to a specific person from origin to destination and gain insights about fuel consumption. This will provide companies the ability to optimize operations through inside data. Cloud-based solutions can be used to measure, control, and keep real-time track of the end-to-end processes.

Ensuring real-time communication and collaboration between various stakeholders is the key to success

Ensuring real-time communication and collaboration between various stakeholders is the key to success. It is only through clear communication that goals can be fulfilled. Relevant information and data should be shared across the production, planning, delivery, and customer services departments. This will empower companies to optimize internal operations and streamline data through all departments.