End to End Supply Chain Management: A Quick Guide

End to end (E2E) in management is a relatively new concept. This approach champions supply chain operations where all the moving parts effectively work together, leading to a more efficient supply chain. From the sourcing of raw materials to delivery of the final product, end to end supply chains communicate efficiently to reduce waste and speed up processes.

E2E is Lean

E2E supply chain management focuses on simplicity. It looks at each process, from beginning to end, and finds a way to make those processes simpler. This simplification could range from a reduction in paperwork wrought by smarter procurement practices to better transportation planning that leads to more effective utilization of staff and equipment.

Supply chains are complicated and making them easier to navigate is necessary for effective end to end management practices. Full integration is nigh on impossible in a supply chain where resources are scattered and chosen differently from one operation to the next. The siloing of the past gives way to produce more visible, efficient operations.

E2E is Incorporative

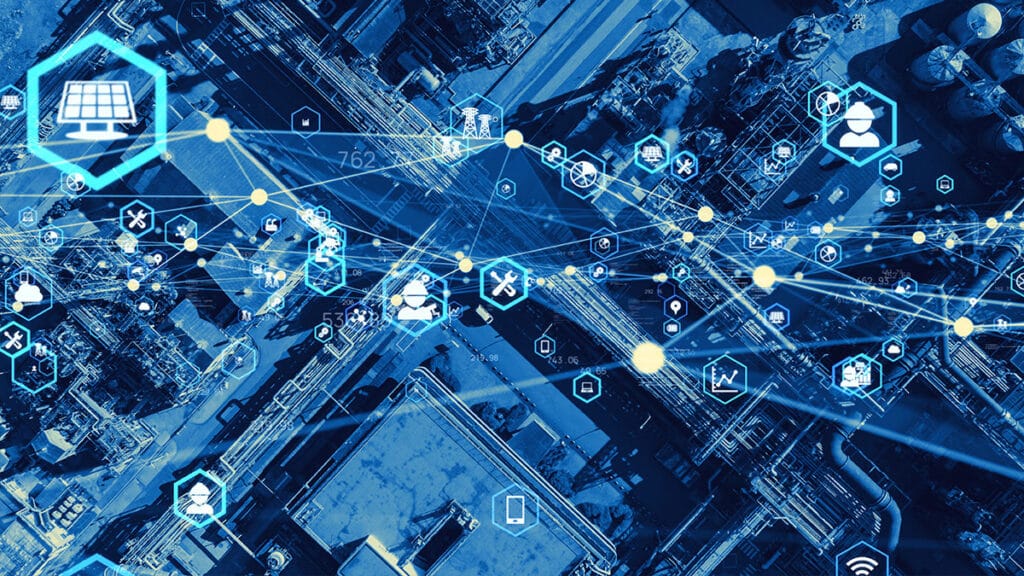

You can’t have a 360¬∞ view of your supply chain if certain sections of it are walled off. End to end supply chain management means turning the doors between departments into windows. It recognizes that every cog in the machine that is your supply chain is interconnected, and that every slip of one single cog affect both the other cogs and the whole organization. Many companies implement an enterprise resource planning system to run various departments, pooling the resources of R&D, procurement, production, logistics, transportation, and HR operations in order to see the big picture.

Another way that E2E is incorporative is that it doesn’t count anyone out. While software and processes are a key to visibility, culture is also a critical factor. Ideas from everyone, from the lowliest assembly line worker to the C-Suite, all have the potential to be valuable. The culture within an E2E supply chain must accept and encourage innovation from every source, looking at problems from every position within the company.

E2E is Disruptive

From the technology to the culture, end to end supply chains are disruptive. They challenge the best practices of the past to create a more effective supply chain through teamwork across the organization. Programs that help with data spread and decision-making in an end to end supply chain are often driven by cutting edge technology like IoT and AI.

E2E is the Future

Supply chain visibility is a top priority for most companies, though the vast majority of companies don’t believe they’ve achieved true visibility. An end to end approach can provide clarity to organizations seeking better visibility by overhauling the status quo.