Supply Chain Planning: 7 Key Steps to Boost Your Business Performance

Behind every successful business lies a well-orchestrated supply chain planning strategy. An efficient supply chain ensures that products are delivered on time, at the right cost, and with optimal quality.

Supply chain demand planning is the backbone of a company’s operations, encompassing the processes and strategies involved in managing the flow of goods, services, and information from raw material suppliers to end consumers. Generally, a company’s supply chain management planning evolves as its demand grows.

Effective supply chain planning can significantly impact a company’s bottom line by minimizing costs, improving customer satisfaction, and enhancing overall business performance. In this post, we’ll dig into the core concepts of supply chain planning and explore seven key steps to optimize your supply chain for success.

Here’s a brief glimpse of each step, before we dive into more detail:

Get Your Free Supply Chain Analysis!

What is Supply Chain Planning?

Supply chain planning is the strategic process of designing, implementing, and managing the flow of goods, services, and information from the point of origin to the point of consumption. Overall, it involves various activities, like demand forecasting, inventory management, production scheduling, supplier management, and logistics optimization.

The primary objective is to ensure that the right products are available at the right place, time, and quantities. An effective supply chain planning process features the following components:

- Demand Forecasting: By understanding future demand patterns, businesses can efficiently align their supply chain processes to meet customer needs.

- Inventory Management: Inventory management involves managing and controlling the levels of raw materials, works-in-progress, and finished goods. It aims to balance having enough inventory to meet customer demand without carrying excess stock.

- Production Scheduling and Capacity Planning: Production scheduling involves planning when and how much to produce. On the other hand, capacity planning evaluates the production capabilities of facilities and workforces to meet varying demand levels.

- Supplier Management: Supplier management focuses on building strong and collaborative relationships with suppliers. It involves selecting reliable partners, negotiating contracts, and monitoring supplier performance.

- Logistics and Distribution: Optimizing logistics and distribution ensures timely delivery, reduces transportation costs, and improves customer satisfaction.

Supply chain planning enables businesses to respond swiftly to changing market conditions, improve operational efficiency, and adapt to customer demands. By optimizing your supply chain, companies can minimize costs, reduce lead times, and gain a competitive edge in their industry.

Now that we’ve set the stage, let’s dive into the seven steps that will empower your organization to master supply chain planning and boost business performance.

Step 1: Assess Current Supply Chain Performance

Before embarking on any supply chain planning initiative, conducting a thorough assessment of your current performance is essential. This evaluation helps identify the strengths and weaknesses of your existing processes, allowing you to make data-driven decisions for improvement.

A SWOT analysis is one of the most evident analysis tools in this step. The SWOT (strengths, weaknesses, opportunities, and threats) analysis is a classic and effective analytical tool that countless leaders use across all industries. This simple yet practical tool allows leaders to determine what aspect of their strategy works and what needs to be improved.

Additionally, assessing supply chain performance involves analyzing key performance indicators (KPIs) such as inventory turnover, order fulfillment rate, on-time delivery, and customer satisfaction. By understanding where your supply chain excels and falls short, you can focus on targeted improvements that yield tangible results.

Step 2: Set Clear Objectives for Supply Chain Planning

Setting clear and specific objectives is crucial to the success of your supply chain planning efforts. Objectives should align with your overall business goals and be measurable to track progress effectively.

Whether you aim to reduce lead times, optimize inventory levels, or enhance customer service, well-defined objectives provide direction and purpose to your planning process. An effective goal-setting framework you can utilize here is the SMART structure.

Moreover, involving key stakeholders from various departments in the objective-setting phase can lead to a more comprehensive and integrated approach. By aligning supply chain objectives with broader business objectives, you can ensure that your planning efforts contribute directly to the success of your organization.

Step 3: Demand Forecasting for Accurate Planning

Accurate demand forecasting is fundamental to supply chain planning as it allows businesses to anticipate customer needs and align production and inventory accordingly. Demand forecasts provide insights into expected sales volumes and patterns, enabling companies to effectively adjust their supply chain processes to meet future demands.

Various demand forecasting methods are available, such as the following:

- Time Series Analysis: Time series analysis is a popular forecasting method that uses historical data to identify patterns and trends over time. It assumes that future demand will follow past patterns.

- Qualitative Methods: Qualitative forecasting methods are subjective and rely on expert judgment rather than historical data to predict future demand. They are often used in situations where historical data is limited or unreliable.

- Causal Models: Causal models establish cause-and-effect relationships between demand and external factors. They are used when a clear connection between demand and specific independent variables exists.

Selecting the appropriate supply chain forecasting method for your business requires careful consideration of factors such as data availability, demand patterns, expertise, purpose, risk tolerance, and cost. As a result, by choosing the right forecasting method, businesses can make more informed decisions and meet customer demands effectively.

Step 4: Inventory Management for Efficient Operations

Effective inventory management is crucial for achieving a well-optimized supply chain. Inventory levels directly impact cost management, cash flow, and customer satisfaction. Maintaining excess inventory ties up capital and increases holding costs, while insufficient inventory can result in stockouts and lost sales.

Strategies like just-in-time (JIT) inventory and safety stock management help balance keeping inventory costs low and ensuring products are available when needed. So, by leveraging technology and supply chain data analytics, businesses can gain better visibility into their inventory levels and make informed decisions to improve efficiency.

Step 5: Streamlined Production and Capacity Planning

Efficient production scheduling and capacity planning are essential for minimizing lead times and ensuring optimal resource utilization. By aligning production schedules with demand forecasts, businesses can prevent bottlenecks and overproduction, leading to cost savings.

Capacity planning involves evaluating the production capabilities of your facilities and workforce to meet varying demand levels. A well-executed capacity planning process enables you to adjust resources proactively, making it easier to handle fluctuations in demand while maintaining operational efficiency.

Step 6: Effective Supplier Management and Sourcing

Suppliers play an important role in the success of your supply chain, as the quality and reliability of your inputs directly impact the end product or service. Effective supplier management involves:

- Selecting reliable partners

- Negotiating contracts that align with your business needs

- Fostering strong, mutually beneficial relationships

When choosing suppliers, consider their financial stability, production capabilities, and track record in delivering on time and meeting quality standards. Regularly assess supplier performance and communicate openly to address issues promptly, fostering a collaborative environment that benefits both parties.

Step 7: Logistics and Distribution Network Optimization

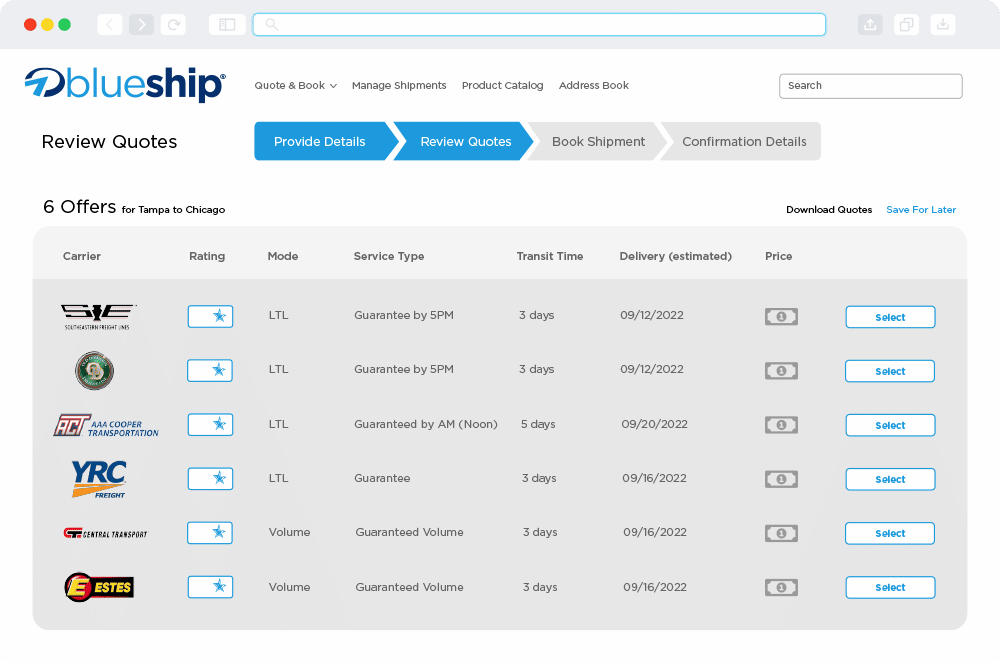

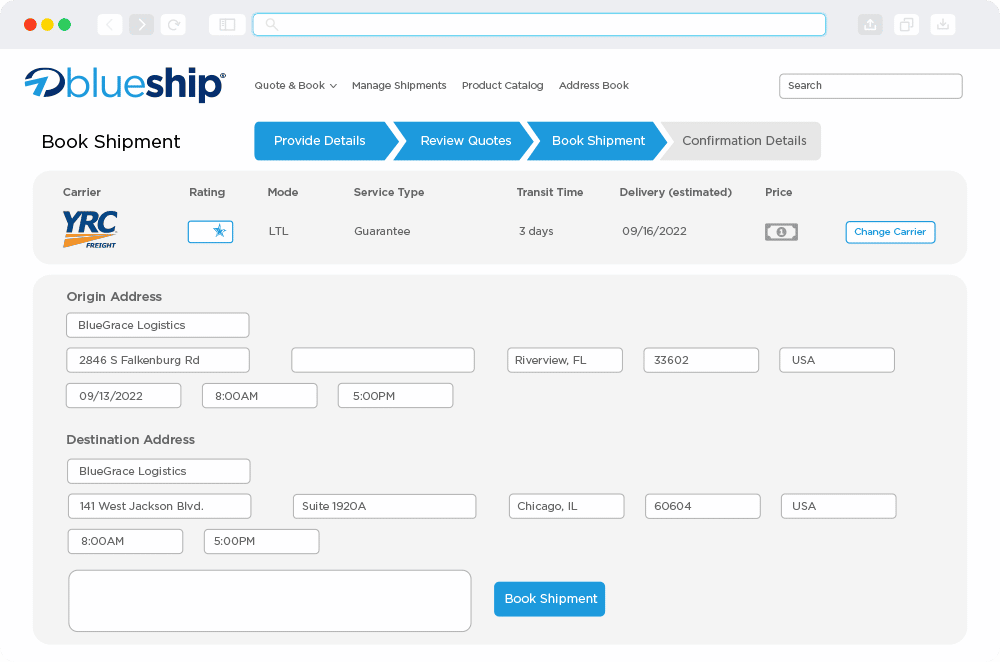

The final step in the supply chain planning process involves optimizing your logistics and distribution network. An efficient transportation and distribution system ensures that products move swiftly from manufacturing facilities to distribution centers and ultimately to the end consumers.

Consider transportation costs, lead times, and service levels when designing your distribution network. Employ data-driven insights and advanced logistics solutions to streamline transportation routes, minimize transit times, and reduce shipping costs.

BlueGrace Logistics Confidence Index: Leveraging Data for Supply Chain Planning

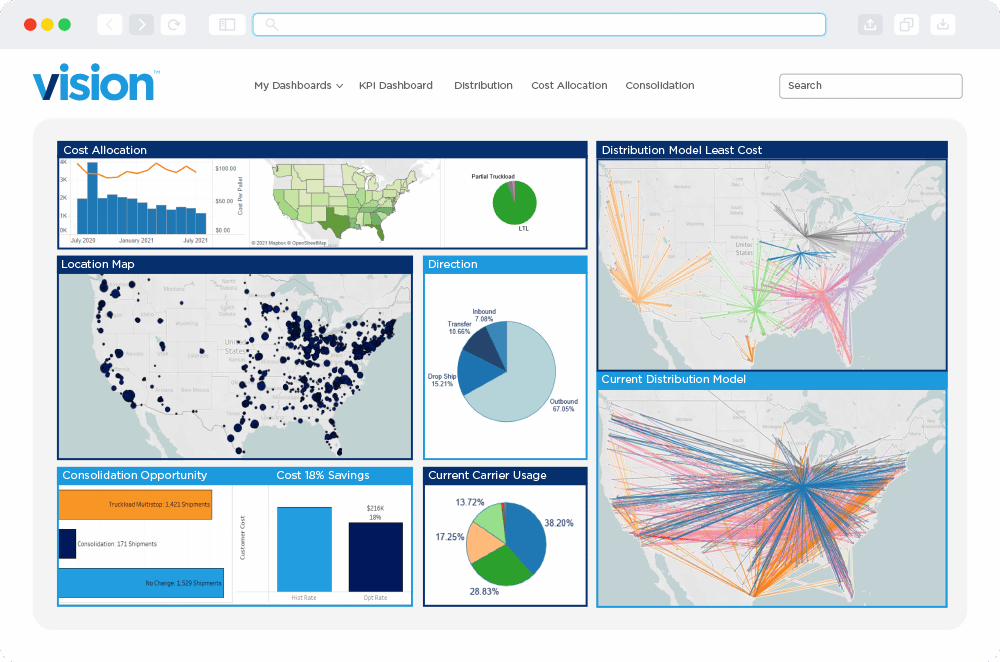

To further enhance your supply chain planning efforts, consider incorporating supply chain planning tools like the BlueGrace Logistics Confidence Index. This valuable tool provides data-driven insights and benchmarks to guide decision-making and support your supply chain strategy.

The BlueGrace Logistics Confidence Index analyzes industry trends, transportation market conditions, and economic indicators to offer a comprehensive outlook on the logistics landscape. By leveraging this data, businesses can make informed decisions, identify potential risks, and optimize their supply chain to stay ahead of the competition.

In Conclusion

Supply chain planning is a critical process that can significantly impact the success of your business. Following the seven key steps outlined in this post can boost performance, improve operational efficiency, and enhance customer satisfaction.

Remember to assess your current supply chain performance, set clear objectives aligned with business goals, and leverage demand forecasting to anticipate customer needs accurately. Additionally, focus on inventory management, streamlined production, effective supplier management, and optimized logistics to achieve a well-structured and efficient supply chain.

Lastly, incorporate the BlueGrace Logistics Confidence Index to gain valuable data insights and make data-driven decisions that enhance your supply chain planning efforts. By embracing these strategies and tools, your business can thrive in today’s dynamic and competitive marketplace.

Looking to chat further regarding your supply chain planning strategy and implementation? Speak with a BlueGrace expert and get a free supply chain analysis today!

Related Posts

Predictive and Prescriptive Analytics in Logistics

Predictive and Prescriptive Analytics in Logistics

View Whitepaper

Shipper’s Guide to Planning Ahead

Shipper’s Guide to Planning Ahead

Read News

How to Use Predictive and Prescriptive Analytics to Benefit Your Supply Chain

How to Use Predictive and Prescriptive Analytics to Benefit Your Supply Chain

View The Logistics Blog®