A stressed supply chain is making businesses reconsider alternatives. Find out if nearshoring and friendshoring are good options for your business.

A stressed supply chain is making businesses reconsider alternatives. Find out if nearshoring and friendshoring are good options for your business.

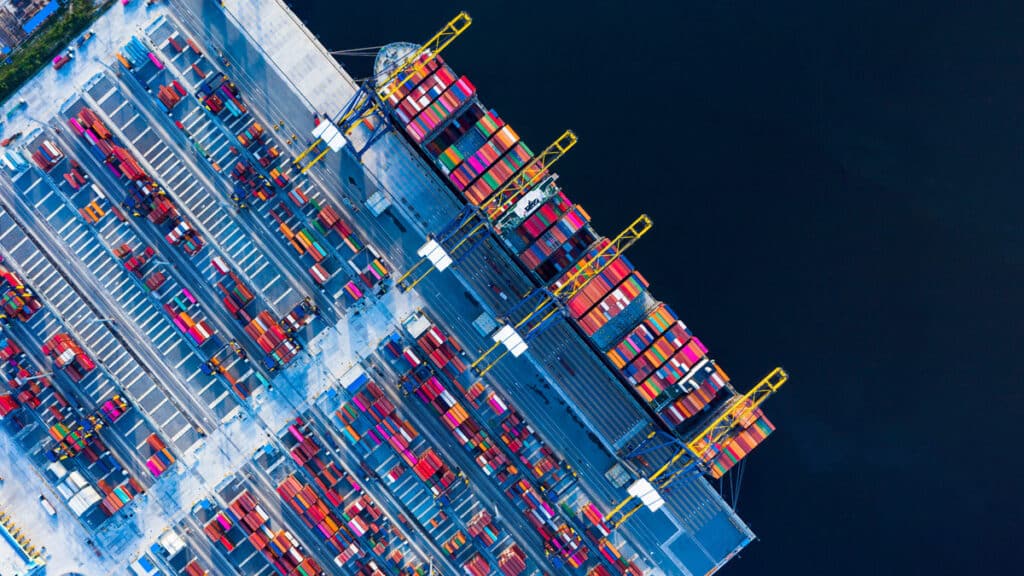

The global supply chain has been stressed by things like COVID-19, inflation, labor shortages, overwhelmed ports stranding cargo ships offshore, increased reliance on China, and the war in Ukraine. This has led businesses to reconsider their trade and manufacturing practices.

Two strategies that have become more common to hear about are nearshoring and friendshoring. What are these practices, how do they differ, and what could it mean to adapt them to your business plans?

Nearshoring is the act of relocating business operations to a nearby country, commonly with a shared border, like Mexico. An increasing number of companies are investing in plans to relocate closer to their target markets. So it’s not surprising that the Trade in Transition 2023 global report found that nearshoring has increased by 8 percent since 2021. And McKinsey and Company reported that some manufacturers, especially in the apparel industry, are employing nearshoring and automation to boost profitability and their competitive stance online.

Nearshoring has its advantages.

This approach can:

Although nearshoring can be beneficial, it can be costly and time-consuming to implement since you are relocating operations to a different geographic location. Employing this strategy can potentially increase the cost to manufacture the product, leading to increased product costs or decreased profits.

Friendshoring is a term coined by the White House and Treasury Secretary Janet Yellen who spoke about friendshoring during her visit to Toronto last June. The practice of friendshoring shifts to suppliers in countries perceived as politically and economically safe or low-risk to avoid or minimize supply chain disruptions due to geopolitical issues.

The US government has already started to redirect its sourcing for components and raw materials to “friendly” countries with shared values to increase domestic production. And, Apple has also implemented friendshoring by taking steps to relocate some of its iPhone production to India from China. (link)

The perks of relocating operations to allied territories enable you to maintain close relationships with trade partners and more closely monitor operations.

This strategy can also help you build a more resilient supply chain.

Friendshoring has its issues. Identifying “friends” in such a complex and continually evolving geopolitical environment can be challenging. And the World Trade Organization predicted that a split in global trading into Eastern and Western could potentially result in a 5 percent drop in G.D.P. Plus, there is a chance that shifting to politically favorable partners could make your products more costly.

Another consideration is that shifting from an established partnership to a new one, regardless of the reason, carries quality, reliability, and overall performance risks.

Another consideration is that shifting from an established partnership to a new one, regardless of the reason, carries quality, reliability, and overall performance risks. The transition period requires active management to ensure the old supplier, receiving less or maybe no future business from you, continues to perform as you ramp up your new supplier. Plus, there is always the possibility that a competitor could take up with the supplier you are transitioning from, threatening the availability of materials from that source.

Nearshoring and friendshoring aren’t for everyone. If your supply chain is working well with your current global partners, it may not be time to make any changes at this point.

But, if you have been experiencing frequent disruptions in manufacturing and transportation, these may be viable options to consider.

Get expert logistics insights delivered straight to your inbox

"*" indicates required fields

Notifications