How to Ship Frozen Food Like a Pro: 5 Tips for Business Success

Shipping frozen food is no small task for businesses. It entails intricate cold chain logistics practices, where expertise can streamline your operations into a highly efficient, cost-effective system. Whether you’re a startup aiming to launch with a successful shipping strategy or a seasoned industry veteran looking to fine-tune, there’s always room to refine your approach. It’s not just about getting from point A to point B; it’s about doing it smarter.

In this journey towards how to ship frozen food like a pro, we’ll uncover five tips that have the potential to transform your shipping practices, boost efficiency, and optimize costs. This isn’t just about the ‘how’, it’s about the ‘how to excel’. But why stop there, we’ll also dive into the ‘who’. Who can help you on this journey? Finding the perfect shipping partner tailored to your unique needs can be a game-changer.

So, let’s dive into the secrets of frozen food shipping and help your business glide towards a more efficient and successful future.

Tip 1: Assessing Your Frozen Food Inventory

Get Started with a Temperature-Controlled Freight Quote

To ship frozen food like a pro, the first step is gaining a comprehensive view of your frozen food inventory. This visibility is not just essential; it’s the foundation of your success. But why is this step so important?

It provides you with a deep understanding of your inventory, which includes product quantities, variations, and unique characteristics. This knowledge empowers you to make informed logistics decisions, preventing costly overstocking or frustrating understocking scenarios. But it’s not just about quantity; it’s about understanding your product mix. By knowing your inventory inside and out, you can strategically plan your frozen food shipping process, ensuring that the right products are shipped in the right quantities at the right times.

Tip 1 Examples:

- Regularly conduct physical inventory counts to ensure the accuracy of your records. Compare the counts with your inventory management system to identify any discrepancies.

- Use inventory management software to track product quantities, expiration dates, and product characteristics. This software can provide real-time insights into your inventory.

- Implement a demand forecasting system that analyzes historical sales data to predict future inventory needs accurately. This helps prevent overstocking or understocking.

Tip 2: Streamlining Frozen Food Packaging and Materials

Packaging can also play a major role in how to ship frozen food like a pro. It can significantly impact the volume, temperature stability, and weight of your frozen products. However, choosing the right packaging materials is more than just picking a box—it’s about protecting your products while promoting efficiency in your frozen food shipping process.

The selection of packaging materials goes beyond protection; it can also affect your costs and environment. Prioritizing eco-friendly packaging is a smart move in terms of sustainability and your businesses environmental responsibility.

Additionally, it’s essential to opt for materials with physical qualities that optimize shipping. Lightweight and insulating materials, or those that combine both, like styrofoam, can offer substantial benefits. These advantages encompass total cargo weight, energy efficiency for temperature maintenance, and even the ability to reduce the risk of thawing.

While the cost savings from optimized cargo for conditions like weight may seem modest for a single shipment, these cumulative optimizations can save organizations thousands per year.

Tip 2 Examples:

- Select packaging materials specifically designed for frozen food, such as insulated boxes or containers with thermal liners, to ensure temperature control during transit.

- Explore eco-friendly packaging options like biodegradable materials or recyclable packaging. This not only aligns with sustainability goals but can also reduce packaging costs.

- Standardize packaging materials and sizes to minimize the number of variations, making it easier to manage and order supplies efficiently.

Tip 3: Efficient Packaging Techniques for Frozen Food Shipping

Efficient packaging techniques can be vital to optimizing the frozen food shipping process. It’s not merely about speed; it’s about minimizing waste and labor costs while ensuring your products are well-protected.

One effective approach to enhancing speed and efficiency is through automation. This entails automating processes like bagging, case packing, and palletizing. By embracing automation, organizations can not only improve their efficiency and speed, but also enhance their cost-effectiveness. Moreover, highly automated systems often require fewer labor resources.

Bulk packaging to ship frozen food emerges as another valuable technique for reducing business waste and optimizing space. Not only is this practice more sustainable and environmentally responsible, but it’s remarkably more efficient, requiring less space and fewer packaging materials.

Tip 3 Examples:

- Invest in automated packaging equipment that can efficiently package frozen food products, reducing the need for manual labor and increasing output.

- Utilize bulk packaging for items with consistent shapes and sizes to speed up the packaging process and reduce materials and labor costs.

- Train packaging staff in efficient techniques, such as using appropriate-sized boxes and minimizing excess packaging materials, to reduce waste and save on costs.

Tip 4: Enhancing Temperature Control When Shipping Frozen Food

While we’ve briefly touched on temperature control in earlier tips — like using highly insulated materials like styrofoam — the importance of temperature control cannot be overstated. When the temperatures of frozen foods peak too high — often above freezing — their safety and quality can be compromised. Higher temperatures can be conducive to the growth and development of dangerous pathogens and subpar quality.

To address these concerns, it’s important to optimize your temperature-controlled shipping. Fortunately, organizations have multiple approaches to this and cutting-edge technologies at their disposal:

- Temperature-controlled packaging, or cold chain packaging

- Real-time temperature monitoring through temperature indicators

- Refrigerated transport vehicles, like reefer trailers

By enhancing temperature maintenance practices, organizations can operate within tighter temperature ranges, reducing cooling costs and safeguarding the integrity of frozen goods.

Tip 4 Examples:

- Install advanced refrigeration systems in your storage facilities and delivery vehicles to maintain consistent and precise temperature control.

- Use temperature monitoring devices with real-time alerts to ensure that products stay within the required temperature range throughout the frozen food shipping process.

- Explore innovative packaging solutions like thermal-insulated packaging and phase-change materials that help maintain temperature during transit without excessive energy consumption.

Tip 5: Optimizing Tracking and Shipping Frozen Foods

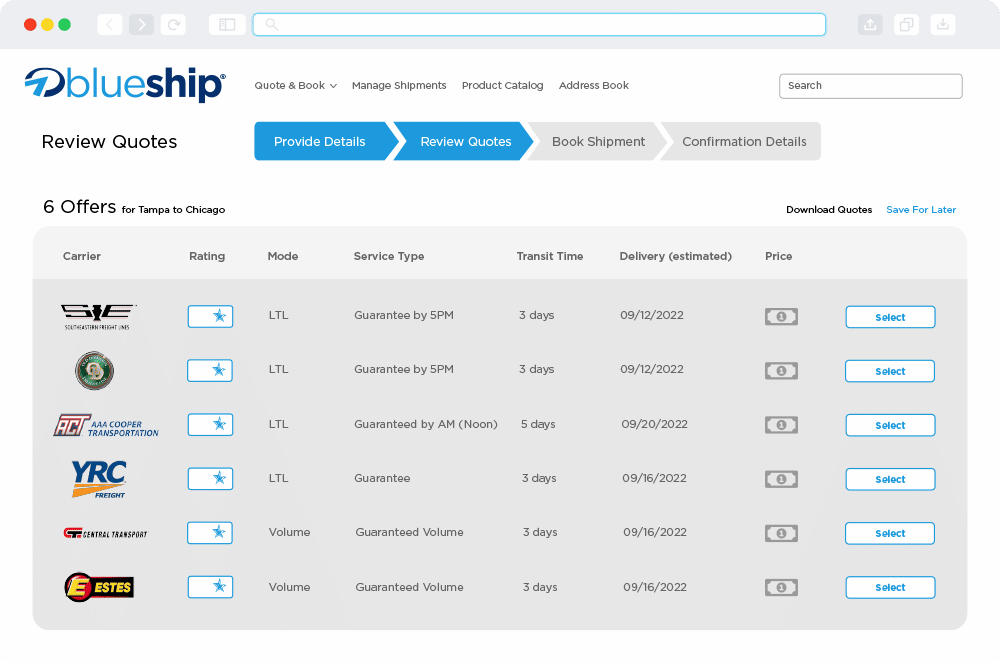

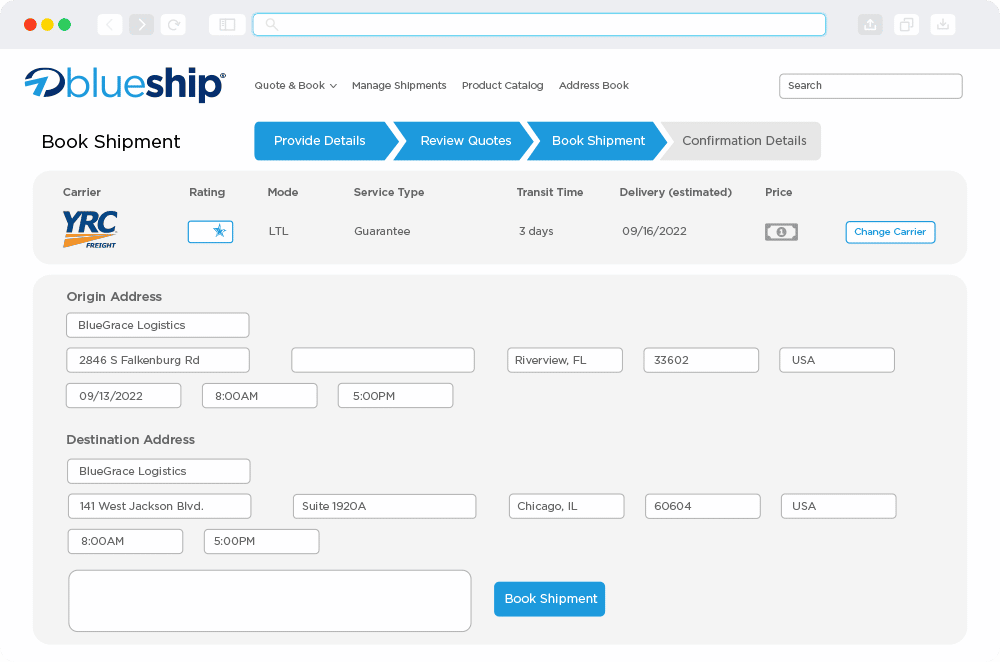

Finally, optimizing the shipments themselves can be crucial in enhancing your frozen food shipping practices. Organizations can achieve this by streamlining shipping routes, minimizing travel distances, and reducing cooling and fuel costs. Selecting carriers known for efficient and cost-effective services can further contribute to this success.

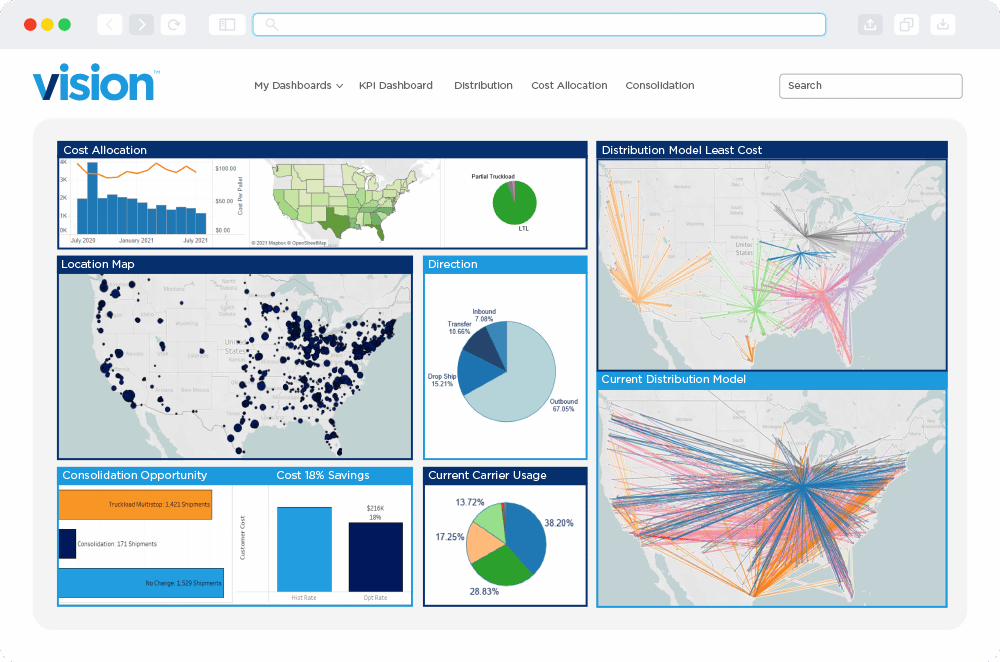

Additionally, real-time tracking and supply chain analytics can help drive data-informed action. Historical frozen food shipping data can be used to develop more efficient routes, while real-time tracking can enable organizations to proactively address delays.

Tip 5 Examples:

- Utilize route optimization software to plan delivery routes that minimize travel time, reduce fuel costs, and maximize efficiency.

- Select carriers with a track record of reliability and temperature-controlled capabilities, ensuring that your frozen food products arrive safely and on time.

- Implement real-time tracking and data analytics to monitor shipments in transit. This data can help you identify and address any issues promptly and make informed decisions for future shipments.

Choosing the Right Frozen Food Shipping Partner

While these tips can work wonders for your frozen food shipping efficiency, there’s another ace up your sleeve—collaborating with a specialized Third-Party Logistics (3PL) provider. Finding the right partner can yield remarkable benefits for organizations aiming to optimize their cold chain logistics operations. Partnering with an experienced and reputable third-party logistics provider offers numerous tangible advantages:

- Expertise: Whether your business is learning how to ship frozen food from scratch or already seasoned in the industry, the expertise of a third-party logistics provider can bring valuable expertise to the table. 3PLs specializing in temperature-controlled services have a deep understanding of managing frozen food shipments effectively. They are well-versed in the unique requirements and challenges of maintaining the necessary temperature throughout the supply chain, ensuring the safe and timely delivery of your goods.

- Cost Savings: 3PLs can often achieve cost savings through economies of scale. They can consolidate shipments from multiple clients, reducing transportation costs. Additionally, their expertise in optimizing routes and minimizing transit times can lead to cost reductions.

- Scalability: They can adapt to a business’s changing needs. Whether you have seasonal fluctuations in demand or are expanding your product line, a 3PL can scale its services accordingly.

- Tailored Solutions: A specialized 3PL can provide tailored solutions to address the unique challenges and requirements of shipping frozen food, ensuring that your logistics approach aligns perfectly with your business goals.

- Risk Mitigation: Collaborating with a reputable partner can help mitigate the risks associated with frozen food shipping. They often have robust contingency plans and industry-specific knowledge to handle unexpected situations and maintain product quality.

The Bottom Line

Learning how to ship frozen food isn’t reserved for industry veterans. By following these five comprehensive steps and considering a strategic partnership, businesses of all sizes can enhance efficiency, reduce costs, and maintain product quality. Take the initiative to assess your inventory, streamline your packaging, improve temperature control, optimize shipping routes, and leverage real-time tracking and data analytics. The road to shipping like a pro is within your reach.

Ready to optimize your frozen food shipping and take your business to the next level? Get a free temperature-controlled freight quote today and discover how partnering with BlueGrace can revolutionize your logistics operations.

Related Posts

Inbound Logistics Programs for Retailers and Distributors During the Domestic Produce Season

Inbound Logistics Programs for Retailers and Distributors During the Domestic Produce Season

View Whitepaper

BlueGrace Logistics Named A 2023 Top 3PL And Cold Storage Provider

BlueGrace Logistics Named A 2023 Top 3PL And Cold Storage Provider

Read News

2022 Reefer Roundtable

2022 Reefer Roundtable

View Webinars