How to Conduct a Supply Chain Analysis for Your Business

In freight shipping, supply chain optimization is the key to staying ahead of the competition. A well-executed supply chain analysis can be a game-changer, providing valuable insights that lead to enhanced efficiencies, cost reduction and improved customer satisfaction. Whether you’re a small startup or an established enterprise, understanding and fine-tuning your supply chain is essential for long-term success.

In this post, we’ll walk you through a step-by-step process of conducting a supply chain analysis and how to tailor to your unique business’s needs. From defining clear objectives to unlocking actionable recommendations, we will equip you with the knowledge and tools to transform your supply chain into a strategic advantage.

Understanding a Supply Chain Analysis

Before diving into the process, let’s emphasize the importance of a supply chain analysis. A well-executed analysis helps businesses gain a holistic view of their supply chain, from sourcing raw materials to delivering the final product to customers.

Certainly, this understanding empowers companies to streamline operations, enhance collaboration with suppliers and partners, and ultimately achieve a competitive advantage.

Get Your Free Supply Chain Analysis!

The seven essential steps in the analysis of supply chain health are as follows:

- Setting Objectives and Scope: What aspects of the supply chain are you looking to optimize?

- Data Collection and Preparation: Collect data from all relevant sources, including suppliers, transportation partners, and internal systems.

- Mapping the Supply Chain: Look for patterns, trends, and areas where inefficiencies may exist.

- Performance Metrics and KPIs: Define key performance indicators (KPIs) to measure the success of your supply chain.

- Identifying Weak Points and Bottlenecks: Pinpoint areas of the supply chain where bottlenecks and delays occur.

- Risk Assessment and Mitigation: Assess potential risks that could disrupt the supply chain and develop contingency plans to address them.

- Cost Analysis and Optimization: Analyze costs and balance meeting demand and minimizing excess stock.

Now, we’ll break down each step, explaining them in more detail, to get a better understanding of the process.

Step 1: Setting Objectives and Scope

Firstly, it’s essential to establish clear objectives and define the scope of your supply chain analysis. Ask yourself, what are you looking to achieve? Do you want to focus on cost reduction, improved efficiency or enhancing customer service?

Clearly outlining your goals and setting up a solid supply chain plan will help you stay focused throughout the analysis process. Additionally, define the specific procedures, products, or regions the analysis covers to ensure a comprehensive evaluation.

- Cost Reduction: If cost reduction is a primary objective, consider identifying areas of waste, inefficient processes, and opportunities for cost-saving initiatives. So, this could involve analyzing transportation expenses, inventory carrying costs, and supplier pricing.

- Improved Efficiency: For businesses seeking improved efficiency, the focus might be streamlining processes, reducing lead times, and minimizing delays.

- Better Customer Service: For companies prioritizing customer service, the analysis should emphasize on-time delivery rates, order fulfillment accuracy, and responsiveness to customer demands.

Step 2: Data Collection and Preparation

Accurate and relevant data is the foundation of a successful supply chain analysis. Identify the key data points and metrics vital to understanding your supply chain’s performance. Generally, this may include inventory levels, lead times, transportation costs, order fulfillment rates, supplier performance, etc.

Gather data from various sources, such as enterprise resource planning (ERP) system or a transportation management system (TMS), inventory records, transportation data, and supplier performance reports. Ensure that the data is up-to-date and consistent to facilitate meaningful analysis.

Collaboration with various departments and stakeholders is necessary to gather the required data. IT teams can help extract information from each system, while inventory managers and procurement officers can provide inventory and supplier data.

To conduct a successful supply chain analysis, it is important to pay meticulous attention to data accuracy and completeness. Overall, poor data quality can result in flawed evaluation, leading to misguided decisions that may hamper your business’s potential. So, ensure that part of your process is to verify and clean data before proceeding.

Step 3: Mapping the Supply Chain

Visualizing your supply chain is a powerful way to gain insights into its complexities. For this reason, create a comprehensive visual representation that includes all entities, from suppliers and manufacturers to distributors and customers.

Understand the flow of materials, information, and funds throughout the supply chain. This mapping will help identify dependencies, potential bottlenecks, and areas for improvement.

- Supply Chain Mapping Tools: Utilize supply chain mapping software or visualization tools to represent the supply chain network. These tools can provide a holistic view of your supply chain, facilitating a better understanding of the relationships between different entities.

- Value Stream Mapping: For a more detailed analysis, consider using value stream mapping techniques to identify inefficiencies and areas where value is added or wasted in the supply chain.

Step 4: Performance Metrics and KPIs

To assess various aspects of your supply chain, you must establish relevant performance metrics and key performance indicators (KPIs).

Metrics like inventory turnover ratio, order fulfillment cycle time, on-time delivery rate, and return rate are essential in measuring performance. Then, calculate and interpret these metrics to evaluate the efficiency of your supply chain and identify areas that require attention.

- Performance Benchmarking: Compare your supply chain’s performance metrics with industry standards or best-in-class companies to gain insights into your relative performance. In fact, benchmarking can reveal areas of excellence and areas that need improvement.

- Balanced Scorecard: Implement a balanced scorecard approach to assess supply chain performance from multiple perspectives, including financial, customer, internal processes, and learning and growth.

Step 5: Identifying Weak Points and Bottlenecks

After that, analyze the collected data to identify inefficiencies and bottlenecks within your supply chain. Common issues like excess inventory, long lead times, or unreliable suppliers can significantly impact your overall performance.

Pinpointing these weak points empowers you to address them effectively, leading to streamlined operations and improved customer satisfaction. So, here are some techniques you can utilize:

- Root Cause Analysis: Use root cause analysis techniques to dig deeper into the underlying causes of identified issues. This approach helps to uncover the genuine reasons behind obstacles and inefficiencies.

- Continuous Improvement: A supply chain analysis is not a one-time event — it should be an ongoing process to identify and address new challenges that arise due to changes in the business environment.

Step 6: Risk Assessment and Mitigation

Supply chains are susceptible to risks ranging from natural disasters to supplier disruptions and demand fluctuations. As a result, assessing these risks and developing strategies to mitigate their potential impact is crucial.

Additionally, consider implementing risk management measures to fortify your supply chain, enhancing its resilience against unforeseen challenges. Here are some supply chain risk analysis methods you can apply:

- Risk Mapping: Create a risk map that identifies potential risks and their impact on your supply chain. Consider risks related to suppliers, geopolitical factors, natural disasters, and regulation changes.

- Risk Mitigation Strategies: Develop risk mitigation strategies that include contingency plans, diversification of suppliers, safety stock planning, and proactive risk monitoring.

Step 7: Cost Analysis and Optimization

Lastly, cost optimization plays a vital role in driving profitability within any supply chain. Analyze the various cost components, including transportation, warehousing, inventory holding, and procurement costs.

For instance, identify areas where cost reduction is possible without compromising quality or customer service. Strategies like route optimization, supplier consolidation, and inventory right-sizing can significantly impact the bottom line.

- Total Cost of Ownership (TCO): Consider the TCO approach, which includes direct and indirect costs associated with products and services throughout their lifecycle.

- Collaboration and Negotiation: Engage in collaborative relationships with suppliers and transportation partners to negotiate favorable terms and explore cost-saving opportunities.

Supply Chain Analysis Tools and Technology

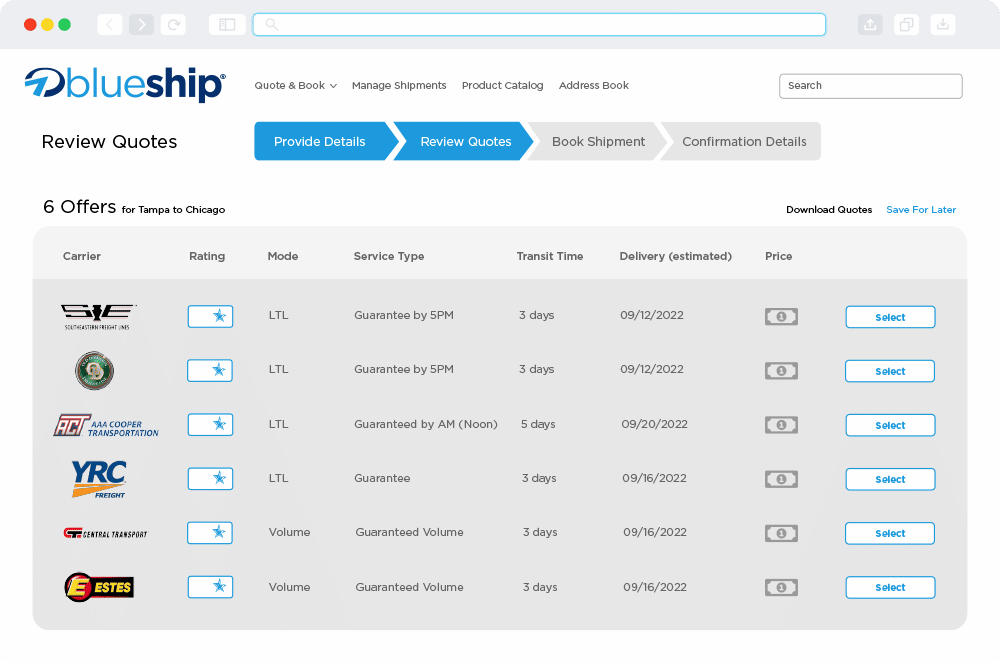

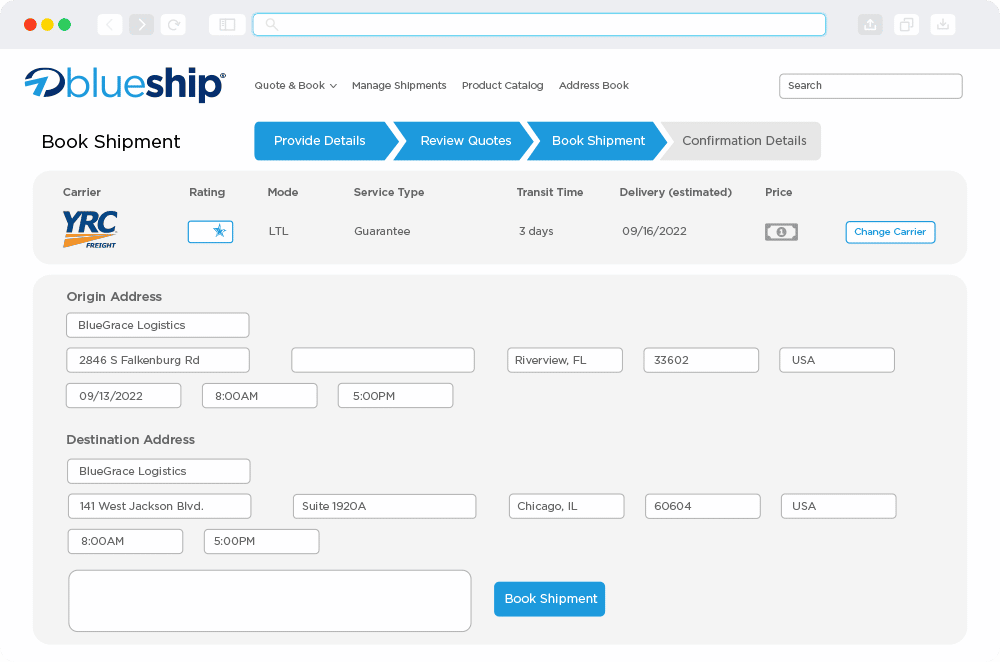

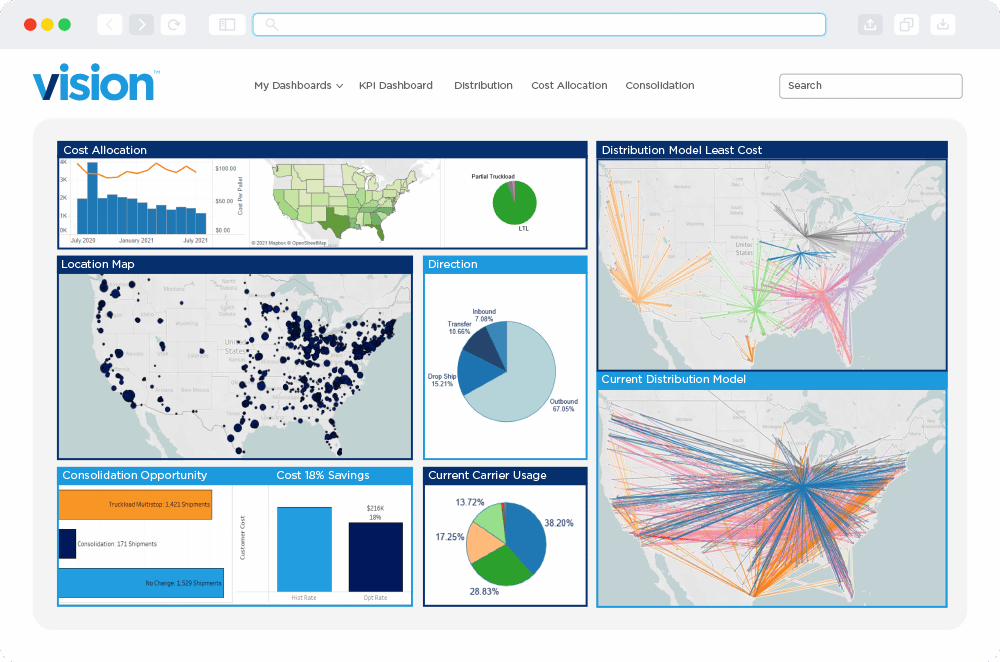

Supply chain analysis tools are essential in conducting a supply chain analysis and optimization. For example, predictive analytics enable businesses to forecast demand more accurately, allowing for better inventory planning and reduced stockouts.

However, advanced analytics can also help you make data-driven decisions that optimize logistics routes, reduce transit times, and minimize fuel consumption.

One innovative tool that businesses can utilize is the BlueGrace Confidence Index. This index assesses a supply chain’s overall health and performance comprehensively.

By evaluating factors such as on-time performance, carrier utilization, and invoice accuracy, the Confidence Index provides a valuable benchmark for businesses to gauge their supply chain efficiency and identify areas for improvement.

Creating Actionable Recommendations

After completing your supply chain analysis, it’s time to transform the insights gained into actionable recommendations. Then, summarize the findings of the analysis and highlight critical areas for improvement.

Focus on practical, implementable strategies that align with the objectives you set earlier. Some actionable recommendations may include:

- Supplier Collaboration: Strengthen relationships with key suppliers to enhance supply chain visibility and streamline the flow of goods.

- Invest in Technology: Implement advanced supply chain management software and analytics tools to optimize various aspects of the supply chain.

- Process Streamlining: Identify and eliminate redundant processes to reduce lead times and improve efficiency.

- Risk Management: Develop robust contingency plans to mitigate risks disrupting the supply chain.

- Continuous Improvement: Foster a culture of constant improvement within the organization to adapt to changing market dynamics and customer demands.

Wrapping Up

Overall, conducting a thorough supply chain analysis is important for freight shippers and logistics professionals aiming for business success. By setting clear objectives, collecting relevant data, mapping the supply chain, and evaluating performance, your business can identify areas for improvement and optimize your supply chain operations. In fact, continuous monitoring and analysis are essential to adapt to changing market conditions and maintain a competitive edge.

Do you need help conducting a supply chain analysis for your business? BlueGrace would love to help! Our team of experts are well-versed in supply chain optimization and can assist you in making data-driven decisions to enhance your business’s performance. Contact us today for a free consultation and unlock the full potential of your supply chain.

Related Posts

Predictive and Prescriptive Analytics in Logistics

Predictive and Prescriptive Analytics in Logistics

View Whitepaper

How to Use Predictive and Prescriptive Analytics to Benefit Your Supply Chain

How to Use Predictive and Prescriptive Analytics to Benefit Your Supply Chain

View The Logistics Blog®

Predictive and Prescriptive Analytics - FreightWaves NOW Interview

Predictive and Prescriptive Analytics - FreightWaves NOW Interview

Read News