Temperature-Controlled Shipping: A Shipper’s Guide to Cold Chain Management

Shipping temperature-sensitive products is a common challenge across industries, with a direct impact on the safety and quality of shipped goods. Enter the world of cold chain logistics—a specialized domain dedicated to transporting perishable items while maintaining precise temperatures.

As each season presents its unique challenges, whether it’s the heat of summer months or the bitter cold of winter, temperature-controlled shipping stands out as a vital solution. In 2022, the cold chain market reached $67 billion and expects to soar past $104 billion in the next 5 years. But what is it exactly, why does it matter for cold chain management, and what strategies can you employ for shipping temperature-sensitive products? In this article, we explore everything you need to know about temperature-controlled shipping and cold chain management for actionable, safe shipping solutions.

Here’s a brief glimpse of what we’ll cover, before we dig into more detail:

Get Started with a Free Temperature-Controlled Freight Quote

- What are the temperature ranges required for different product categories?

- What is cold chain management and what does it have to do with temperature-controlled shipping?

- What are some challenges shippers face and how can I mitigate those?

- What practical tips can help shippers optimize their temperature-controlled shipping operations?

- Why should I partner with a cold chain management expert?

What is Temperature-Controlled Shipping?

Temperature-controlled shipping, also known as refrigerated shipping or reefer shipping, is a specialized logistics and transportation method that involves maintaining specific temperature ranges for cargo during transit. This process is essential for preserving the quality, safety, and integrity of goods that are sensitive to temperature fluctuations. It is commonly used for a wide variety of products, like:

- Produce

- Vaccines

- Perishable foods

- Refrigerated medications and pharmaceuticals

- Flowers

- And more

Temperature-controlled services are not only critical for safeguarding consumer’s health, but also for enhancing your operations and ensuring reliability throughout the manufacturing and distribution processes.

Why Temperature Control Matters

Temperature control is not just for convenience; it’s a vital factor for numerous industries that manage perishable or temperature-sensitive products and materials. Let’s take a closer look at why temperature-controlled shipping matters across different industries:

In the Food Industry

From fresh produce like strawberries to dairy products and frozen foods, there’s no shortage of temperature-sensitive products in the food industry. These products are highly susceptible to spoilage and bacterial growth, and one misstep in the cold chain management process can significantly risk the health and well-being of customers. Temperature-controlled shipping also plays an important role in preserving the taste, texture, and appearance of food products, extending their shelf life and minimizing food waste. By using precise methods and adhering to regulations, food producers are able to reach diverse markets with varying climates while ensuring the integrity of their products throughout the supply chain.

In the Pharmaceutical Industry

The pharmaceutical industry relies on temperature-controlled shipping to ensure the safe consumption of various products, including vaccines and essential medications. Any pharmaceutical products are highly sensitive to temperature variations and deviations from recommended storage conditions can lead to the degradation of active ingredients, rendering medications less potent or even unsafe for consumption.

Additionally, this industry is heavily regulated, with strict requirements for temperature control and monitoring. Complying with guidelines assures product efficacy, making temperature-controlled shipping essential for keeping patients safe and healthy.

In the Chemical Industry

Many chemical compounds have specific temperature requirements necessary to maintain stability and safety. Deviating from these ranges can trigger chemical reactions or other harmful effects, rendering chemicals volatile and posing significant health risks. Temperature-controlled shipping in the chemical industry isn’t just about preserving product quality; it is the only way to prevent accidents related to improper cold storage, while guaranteeing worker and customer safety.

In the Cosmetics Industry

Temperature-controlled shipping is important in the cosmetic industry due to the temperature-sensitive ingredients in many products. Ingredients like antioxidants and vitamins are susceptible to degradation when exposed to incorrect temperatures, leading to changes in product texture, color, and efficacy. By using temperature-controlled shipping methods, cosmetics companies can ensure their products maintain quality and effectiveness throughout the supply chain, fostering customer trust and brand loyalty.

In the Agriculture Industry

The agriculture industry has its fair share of temperature-sensitive products, like seeds, flowers or plant materials, that require careful handling. These products can easily lose viability and quality if not kept properly. Additionally, temperature-controlled shipping is essential for promoting higher crop yields and satisfying customer expectations for quality produce.

Types of Temperature-Controlled Shipping Methods

In temperature-controlled shipping, there are several primary methods to ensure products remain within the desired temperature range throughout their journey from point A to B. These methods accommodate a variety of cargo types, each with their own unique temperature requirements:

Refrigerated Containers (Reefers)

Refrigerated containers, often referred to as reefers, are a staple in temperature-controlled shipping. Unlike dry vans, these containers feature built-in refrigeration units that can both cool and heat, depending on your freight needs. So whether it’s scorching hot or freezing cold outside, reefers are highly versatile and suitable to transporting a wide range of products, including:

- Perishable goods like fruits, vegetables, dairy products, meat, and seafood

- Pharmaceuticals like vaccines and temperature-sensitive medications

- Frozen foods like ice cream and frozen meats

- Beverages like wine, beer, and soft drinks

- Flowers and plants

Insulated Containers

An insulated container has thick insulation in the walls but without active cooling or heating systems like other forms of temperature-controlled shipping. Instead, these containers rely on the cargo’s initial temperature and external conditions to maintain a steady temperature. They are well-suited for the following transporting:

- Perishable goods, particularly those intended for short distances rather than long-distance journeys, such as chocolate or certain types of produce

- Agriculture products like seeds and plant materials, especially for short-distance trips with limited temperature fluctuations

Temperature-Controlled Warehouses

Temperature-controlled warehouses are storage facilities equipped with advanced climate control systems. These warehouses are important for storing many temperature-sensitive products while they await distribution. However, it’s important to note that warehouse space is in high demand, and vacancy rates tend to be low, making this cold storage method challenging for some organizations. Typical items stored can include:

- Pharmaceuticals, like medications or vaccines, often in large amounts and before mass distribution

- Food products, like frozen goods, before being distributed to retailers, restaurants, and consumers

Temperature Ranges in Temperature-Controlled Shipping

In temperature-controlled shipping, maintaining precise temperature ranges is vital, as different products have distinct requirements. Deviations from these specified temperatures can result in spoilage and degradation, rendering the products unfit for customer use or consumption. Let’s explore some common temperature categories and their applications:

- Frozen Goods: For items requiring deep freezing, such as ice cream or frozen seafood, temperatures range from -10°C to -20°C (14°F to -4°F).

- Chilled Goods: Products like fresh produce and dairy items thrive in a chilled environment, typically between 2°C and 4°C (35.6°F to 39.2°F).

- Pharmaceutical Goods: Vaccines and temperature-sensitive medications remain effective within a range of 2°C to 8°C (35.6°F to 46.4°F).

- Ambient Temperature Goods: Certain items, like cosmetics or chemicals, fare best at room temperature, which falls between 15°C and 25°C (59°F to 77°F).

- Cold-Chain Goods: Some products, including certain pharmaceuticals or specialized foods, require controlled temperatures ranging from 8°C to 14°C (46.4°F to 57.2°F).

These precise temperature controls are essential for ensuring that products arrive at their destinations in peak condition, meeting safety and quality standards.

Cold Chain Management in Temperature-Controlled Shipping

At the heart of temperature-controlled shipping is cold chain logistics – an essential process that ensures the safe transportation of products within the correct temperature range, from their initial production to their final destination. The cold chain management process consists of three primary stages: storage, transportation, and distribution. Let’s dive into each stage and see what it entails:

- Storage: This stage typically begins in a temperature-controlled warehouse, equipped with HVAC systems to regulate the temperature of products. Here, implementing temperature monitoring systems will help track temperature and humidity levels.

- Transportation: Specialized containers like reefers are the heroes of temperature-controlled shipping. They maintain the desired temperature conditions and are ideal for long-distance transportation by road, sea, and air.

- Distribution: This stage covers the last-mile delivery process, transporting the product to the customer or final destination. Using refrigerated vehicles during this process will minimize the time products spend outside their desired temperature range.

Challenges and Solutions in Temperature-Controlled Shipping

The temperature-controlled shipping process can present unique challenges that impact the safety and quality of transported goods. While modern temperature-controlled services are highly advanced, there are always potential risks associated with these products. Here are some common challenges you may face, with practical solution on how to address:

Challenge 1: Temperature Fluctuations During Transit

Solution: Implement Advanced Monitoring Systems

Maintaining a consistent temperature throughout the shipping process can be challenging, especially during long journeys or when transferring products between different modes of transportation. To mitigate this challenge, advanced monitoring systems equipped with real-time tracking and alarms should be put in place. These systems promptly detect and address temperature fluctuations, ensuring that the cargo remains within the desired temperature range.

Challenge 2: Power Supply Issues

Solution: Utilize Backup Power Sources

Power interruptions can happen anytime, no matter how diligent you are with your temperature-controlled logistics. These interruptions can lead to refrigeration system failures, jeopardizing the temperature integrity of your cargo. Mitigating this challenge is possible by preparing backup power sources, like generators or battery backups, readily available to ensure continuous power supply, even during outages. Additionally, equipping your reefers with alarms to properly notify you of power disruptions occurs can further enhance risk mitigation.

Challenge 3: Equipment Breakdowns

Solution: Schedule Regular Maintenance

Even with meticulous cold chain management, equipment breakdowns can still occur, posing a risk to temperature-sensitive cargo. Preventing these breakdowns requires regular equipment inspections to ensure everything functions smoothly. Your organization can proactively maintain spare parts and repair resources to quickly address any equipment issues, ensuring uninterrupted temperature-controlled shipping operations.

By addressing these challenges and implementing proactive solutions and best practices, your businesses temperature-controlled shipping can operate smoothly and ensure the safe, reliable transport of your products.

Tips for Shipping Temperature-Controlled

Still uncertain about your temperature-controlled shipping solution? These tips will help you master cold chain management with ease:

- Choose the Right Containers: Opt for specialized containers like reefers to provide precise temperature control during long-distance shipments.

- Proper Cargo Handling: Ensure proper loading and unloading, with all products pre-cooled and stored at optimal temperatures before transportation.

- Implement Temperature Monitoring: Use temperature monitoring solutions to track temperature and address any issues quickly.

- Training: Provide training for employees handling temperature-sensitive materials or managing temperature-controlled shipping processes.

- Emergency Response Plan: Have a contingency plan in place for addressing unavoidable errors.

- Optimize Transportation Routes: Plan transportation routes that minimize products’ exposure to extreme temperatures.

Partner with BlueGrace for All Your Cold Chain Management Needs

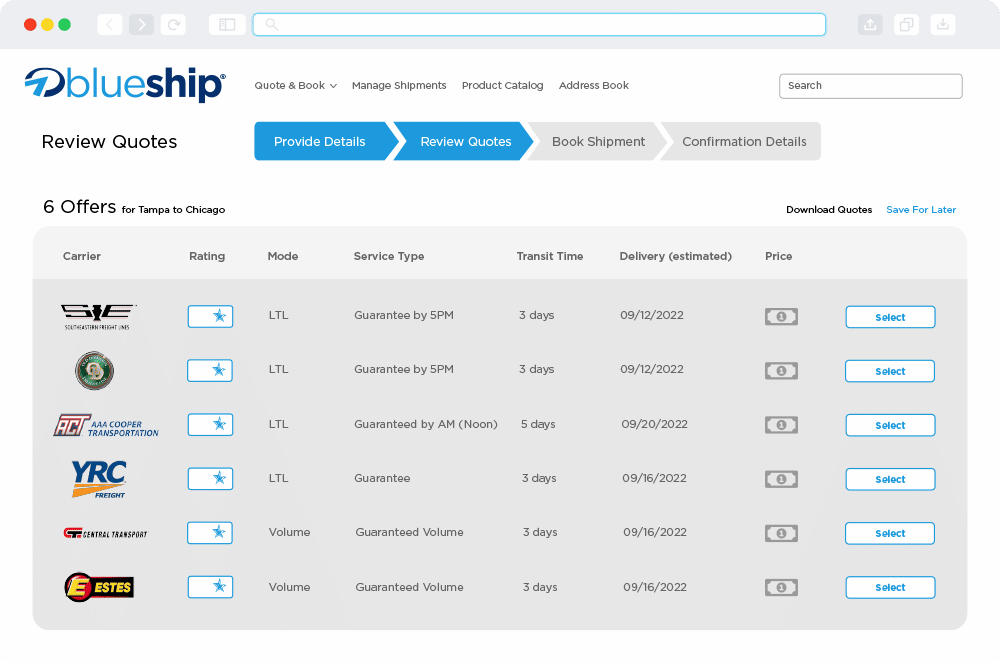

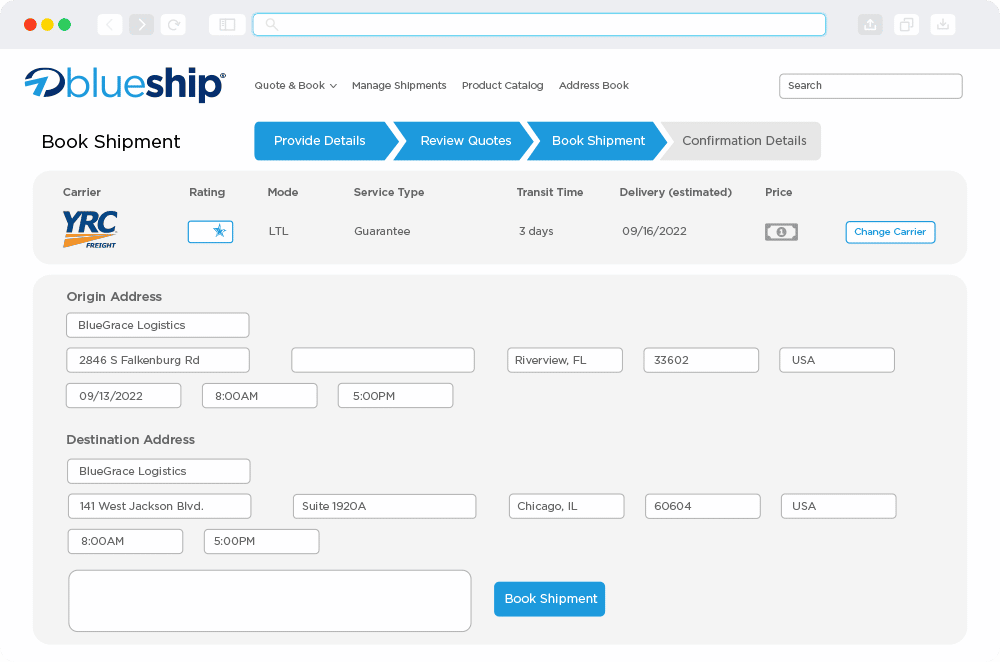

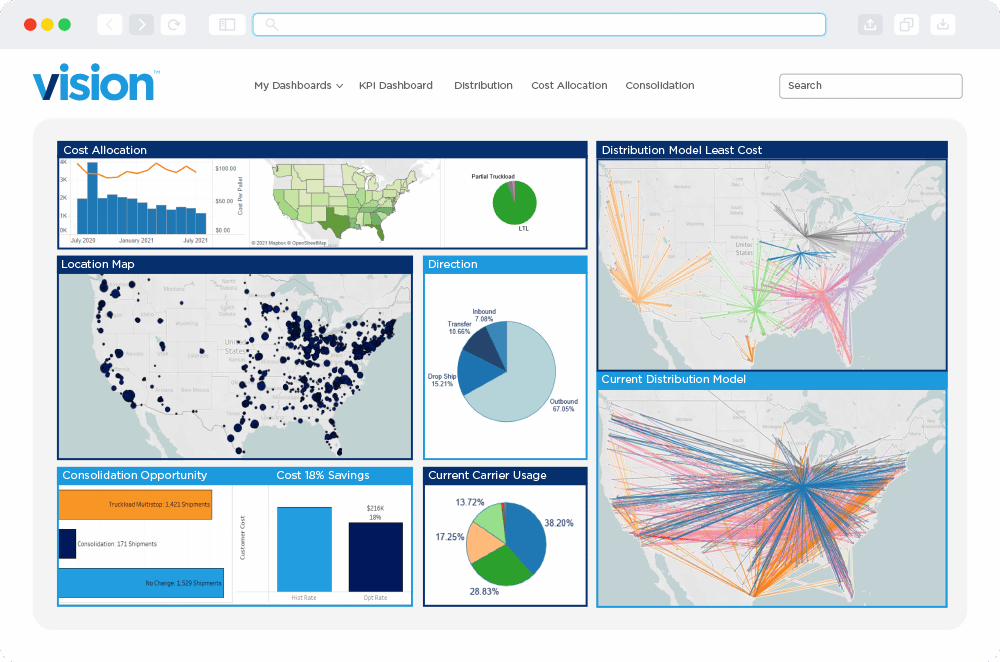

From perishable produce to life-saving pharmaceuticals, there’s no denying the importance of temperature-controlled shipping in preserving product quality and safety. At BlueGrace, we understand the delicate balance required to maintain the integrity of your cargo throughout its journey. Our dedicated team and advanced technology solutions are here to empower your business, providing the confidence you need to meet the demands of the supply chain.

Don’t leave the quality and safety of your products to chance. Partner with BlueGrace and experience a new level of cold chain management. Get a free temperature-controlled freight quote today and take the first step toward a safer, more reliable shipping experience!

Related Posts

Inbound Logistics Programs for Retailers and Distributors During the Domestic Produce Season

Inbound Logistics Programs for Retailers and Distributors During the Domestic Produce Season

View Whitepaper

BlueGrace Logistics Named A 2023 Top 3PL And Cold Storage Provider

BlueGrace Logistics Named A 2023 Top 3PL And Cold Storage Provider

Read News

2022 Reefer Roundtable

2022 Reefer Roundtable

View Webinars